DAIRY AND PHARMA FITTING VALVES

Product Overview

Saakar Solution specializes in premium dairy and pharma fitting valves crafted from high-grade stainless steel for hygienic, sanitary applications in food processing and pharmaceutical industries.

These valves ensure sterile flow control with smooth surfaces, crevice-free designs, and compliance for clean-in-place (CIP) and sterilize-in-place (SIP) processes. Available in types like ball, butterfly, check, diaphragm, and plug valves in grades 304L and 316L, they handle sizes from 1/2" to 6" for precise regulation in dairy lines, pharma piping, and biotech systems.

Ball Valve

Ball valve is a quarter-turn rotary motion valve that uses a ball-shaped disk to stop or start the flow. Most ball valves are of the quick-acting type, which requires a 90° turn of the valve handle to operate the valve. Ball Valves are designed for use in hazardous and corrosive environment. All Ball Valves are preciously machined, designer durability and maximum efficiency to provide high quality and low cost. Low operating torque with SS lever/Phenolic handle. Full or reduced bore for Perfect Flow. Working Pressure from 1000 PSI to 6000 PSI with PTFE seat.

Sizes:1/16” to 1” (OD Tube Fitting); 1/8” to 2”(NPT/BSP/BSPT Threaded)

Material: Stainless Steel (Gr. 304, 316)

Needle Valve

A needle valve is used to accurately control flow rates of clean gasses or fluids. The adjustments are gradual and smooth for controlling the flow rate, however, they can also be used as a reliable shut-off valve. However, they are generally only used for low flow rates and have a relatively large pressure drop from the inlet to the outlet. The flow control at a low rate is very accurate. Flow rates can be adjusted accurately. These valves can shut off easily.

Sizes: 1/16” to 1” (OD Tube Fitting); 1/8” to 2”(NPT/BSP/BSPT Threaded)

Material: Stainless Steel (Gr. 304, 316)

SW Ball Valve

A Socket Weld Ball Valve is used for piping that is 2-inch nominal pipe size (2″ NPS) and smaller. The socket-weld is the easier weld to perform since the pipe is slipped into the close-fitting socket of the valve or fitting, and there is a ready-made pocket in which to lay down the welding material. This weld is usually made with one or two passes, depending on the pipe size.

Sizes:1/2” to 2” (NB Pipe Fitting)

Material: Stainless Steel (Gr. 304, 316, 316L)

Mini Ball Valve

Mini Ball Valves are known for their durability, constant performance and sturdiness. These mini ball valves are very helpful and work very smoothly. These wide ranges for mini ball valves are appreciated for its superior performance, Zero Leakage & Corrosion Free.

Sizes: 1/8” to 3/4” (NPT/BSP/BSPT Threaded)

Material: Brass, Stainless Steel (Gr. 304, 316)

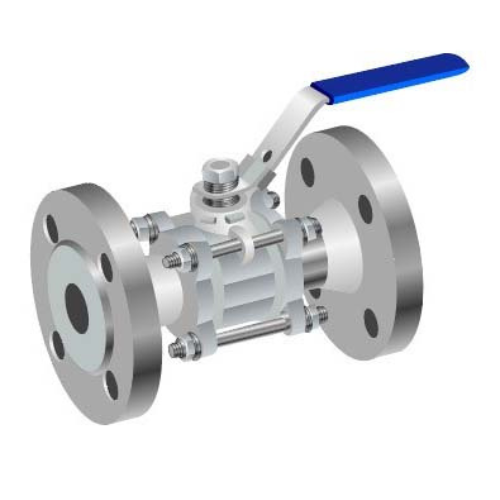

FE Ball Valve

A flange end ball valve refers to a ball valve designed to have flanged ends. It falls into the end-entry valve classification, and is mainly used for shutoff applications for mostly hydraulic circuits. A flanged type ball valve opens and closes the operating fluid flow completely when needed, and is most effective in providing positive leak-tight closure.

Sizes:15 to 150(NB Pipe Fitting)

Class: Table D, Table E, Table F, 150#, 300#

Material: Stainless Steel (Gr. 304, 316)

Gate Valve

A gate valve is the most common type of valve in any process plant. It is a linear motion valve used to start or stop fluid flow. In service, these valves are either in a fully open or fully closed position. Gate valves are used in almost all fluid services such as air, fuel gas, feed water, steam, lube oil, hydrocarbon, and all most any services. The gate valve provides a good shutoff.

Sizes: 1/2” to 2” (NPT/BSP Threaded)

Material: Stainless Steel (Gr. 304, 316)

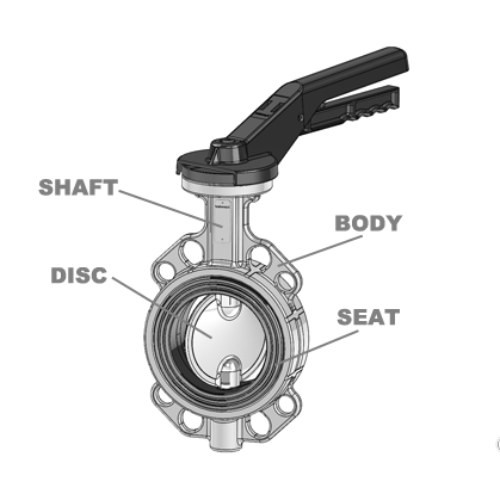

Butterfly Valve

A Butterfly valve is a quarter-turn rotational motion valve that is used to stop, regulate, and start flow. A butterfly valve has a disc which is mounted on a rotating shaft. When the butterfly valve is fully closed, the disk completely blocks the line. When the butterfly valve is fully opened, the disc is at a right angle to the flow of gas or liquid. Their reduced level of wear allows the useful life of the valve to be longer. This reduces direct operating costs and cuts the hours of time required for valve maintenance.

Sizes: 40”NB to 350”NB (Nominal Bore); DN25 to DN600 (DIN)

Material: Stainless Steel (Gr. CF8, CF8M), SGI (Iron Casting), Monel, Inconel, Hastelloy, Duplex and Super Duplex

Safety Valve

Safety valves have spring-loaded pistons. Below their factory-set pressures, internal springs hold the pistons downward, creating a seal. But once the pressure inside a tank or device overcomes the built-in pressure limit of a safety valve, the piston is pushed upwards, opening the valve seal to lower and equalized the air pressure. Safety valves typically also have loops attached to the pistons so that you can manually rapidly depressurize a device or air tank.

Sizes: 1/4” to 1” (NPT/BSP/BSPT Threaded)

Material: Stainless Steel (Gr. 304, 316)

Non Return Valve

NRVs are generally small, simple and inexpensive. It allows a medium to flow in only one direction and is fitted to ensure that the medium flows through a pipe in the right direction, where pressure conditions may otherwise cause reversed flow. They reduce down time and loss of production due to the failure of unsuitable valves.

Sizes:1/16” to 1” (OD Tube Fitting); 1/8” to 2”(NPT/BSP/BSPT Threaded)

Material: Stainless Steel (Gr. 304, 316)

HQR Coupling

Hydraulic Quick Release Coupling are specialized type of disconnect coupling, they are designed to efficiently connect and disconnect fluid lines in hydraulic systems while maintaining fluid pressure and not introducing air. QRC are Fast, Leak proof instant connections, without tools, without twisting or strains. Hence time saving.

Sizes:1/8” to 1” (NPT/BSP/BSPT Threaded)

Material: Stainless Steel (Gr. 304, 316)

Pr Valve

A Pressure Relief Valve is a device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure. It may be provided with enclosed spring housing suitable for closed discharge system application and is primarily used for liquid service.

Sizes: 1/4” to 3” (NPT/BSP/BSPT Threaded)

Material: Stainless Steel (Gr. 304, 316)

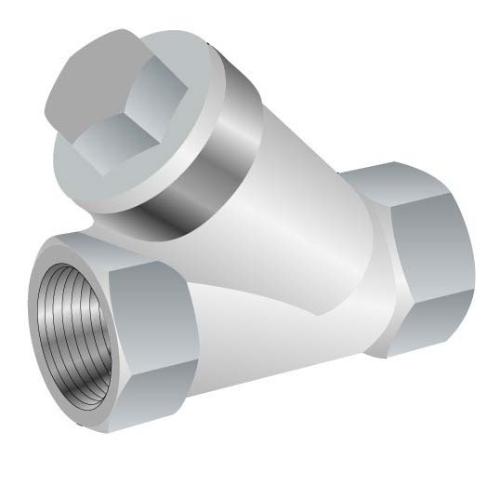

Y-Strainer

Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Sizes:1/2” to 3” (BSP Threaded)

Material: Stainless Steel (Gr. 304, 316)

2-W Manifold Valve

2-Way valve manifolds are designed for connecting system impulse line and transmitters. These Manifolds consist of two valve configuration which allows for easy isolation, calibration, block and bleed for gauges, pressure switches and static pressure transmitting instruments. These manifolds are rugged in construction to withstand high pressures and temperatures. These Manifold Valves combine the functions of a tee, calibration valve, isolation valve and all tubing and fittings into a single compact unit thus reducing number of fittings and space required for installation.

Features:

One Piece Bar stock Forged Body for high strength and fully safety.

Bonnet lock prevents accidents disassembly.

Stem threads rolled and hard plated provides maximum service life.

Two Part Stem tip, stellated and hardened provides excellent flow control and ensures bubble-tight shut off.

Ball Tip design: Which forms a bearing joint with the stem eliminates rotation between plug & seat at closure. This prevents scoring and galling up the valve seat and ensure long life in repetitive shut off service.

Packing below stem threads prevents stem lubrication washout and isolate threads from system fluids.

Hard seat designed to reduce packing friction giving very low torque operation.

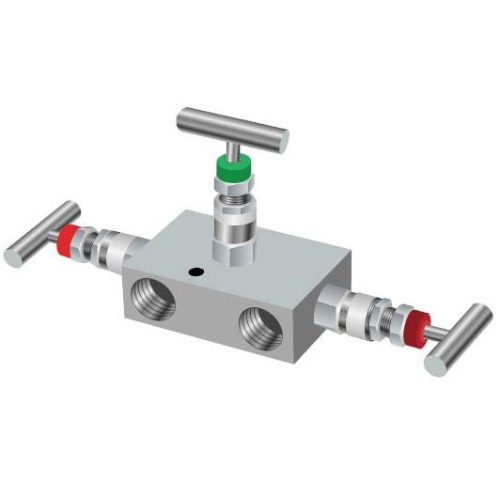

3-W Manifold Valve

3-Way valve manifold is a device that is used to ensure that the capsule will not be over-ranged. It also allows isolation of the transmitter from the process loop. It consists of two block valves – high pressure and low pressure block valve – and an equalizing valve. Two block valves provide instrument isolation, and one equalize valve is positioned between the high and low transmitter process connections to provide equal pressures on both sides.

Features:

One Piece Bar stock Forged Body for high strength and fully safety.

Bonnet lock prevents accidents disassembly.

Stem threads rolled and hard plated provides maximum service life.

Two Part Stem tip, stellated and hardened provides excellent flow control and ensures bubble-tight shut off.

Ball Tip design: Which forms a bearing joint with the stem eliminates rotation between plug & seat at closure. This prevents scoring and galling up the valve seat and ensure long life in repetitive shut off service.

Packing below stem threads prevents stem lubrication washout and isolate threads from system fluids.

Hard seat designed to reduce packing friction giving very low torque operation.

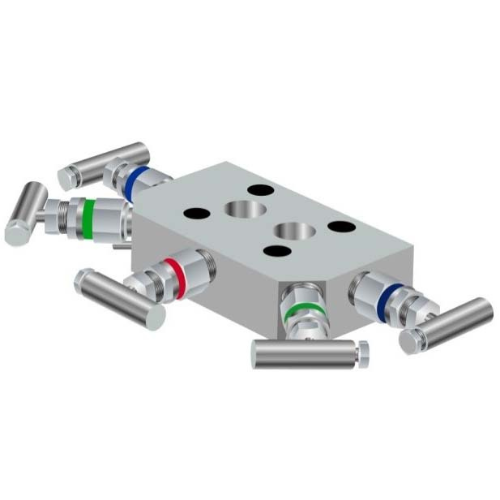

5-W Manifold Valve

5-Way valve manifold is used for differential pressure transmitter. The typical 5-way valve manifold consist of 2 block valve, 1 equalizer valve, and 2 vent or test valve. If we want to check the zero of the transmitter, we just need to close the block valve and open the equalizing valve. If we want to calibrate the transmitter for 3 or 5 point calibration, then after the pressure is equalized we just need to connect the test valve to a pressure generator. This 5-way valve manifold is the most common valve manifold for differential pressure transmitter.

Features:

One Piece Bar stock Forged Body for high strength and fully safety.

Bonnet lock prevents accidents disassembly.

Stem threads rolled and hard plated provides maximum service life.

Two Part Stem tip, stellated and hardened provides excellent flow control and ensures bubble-tight shut off.

Ball Tip design: Which forms a bearing joint with the stem eliminates rotation between plug & seat at closure. This prevents scoring and galling up the valve seat and ensure long life in repetitive shut off service.

Packing below stem threads prevents stem lubrication washout and isolate threads from system fluids.

Hard seat designed to reduce packing friction giving very low torque operation.

Our PRODUCT RANGE